Introduction

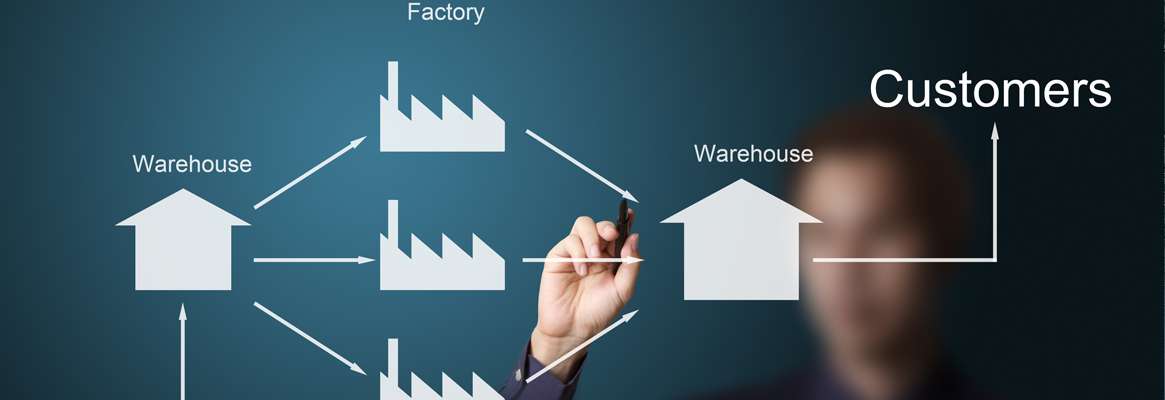

Supply Chain Management (SCM) is the systemic, strategic coordination of the traditional business functions within a particular company and across businesses within the supply chain for the purpose of improving the long-term performance of the individual companies and the supply chain as a whole. A supply chain consists of all parties involved, directly or indirectly in fulfilling a customer request. The supply chain not only includes the manufacturer and the supplier but also transporters, warehouses, retailers, and customers themselves. Within each organization, such as a manufacturer, the supply chain includes all the functions involved in receiving and filling a customer request. A typical supply chain may involve a variety of stages.

These supply chain stages includes,

- Customers

- Retailers

- Wholesalers/Distributors

- Manufacturers

- Component / Raw-material suppliers

Need For Supply Chain Management

Corporations have turned increasingly to global sources for their supplies. This globalization of supply management has forced companies to look for more effective ways to coordinate the flow of materials into and out of the company.

Companies and distribution channels compete more today on the basis of time and quality. Having a defect-free product to the customer faster and more reliably than the competition is no longer seen as competitive advantage but simply a requirement to be in the market. Customers demand products consistently delivered faster, exactly on time, and with no damage. Each of these necessitates closer coordination with supplier and distributors.

The global orientation and increased performance based competition combined with rapidly changing technology and economic conditions all contribute to market place uncertainty. This uncertainty requires great flexibility on the part of individual companies and distribution channels, which in turn demand more flexibility in channel relationship.

All these factors have made the concept of Supply Chain Management more important to companies.

Objective of Supply Chain

The objective of every supply chain is to maximize the overall value generated. The value a supply chain generates is the difference between what the final product is worth to the customer and the cost of supply chain incurs in filling the customer's request. For most commercial supply chains, value will be strongly correlated with supply chain profitability i.e. the difference between the revenue generated from the customer and the overall cost across the supply chain.

Process View of A Supply Chain

The supply chain process occurs in two ways, Cycle View and Push/Pull view.

1. Cycle View

The processes in a supply chain are divided into a series of cycle, each performed at the interface between two successive stages of a supply chain. Cycle view of Supply chain process includes,

- Customer order cycle

- Replenishment cycle

- Manufacturing cycle

- Procurement cycle

2. Push/ Pull view

The processes in a supply chain are dividing into two categories depending on whether they are executed in response to a customer order or in anticipation of customer orders. Pull process are initiated by a customer order, whereas push process are initiated and performed in anticipation of customer orders.

Supply Chain Management in Global Environment

The globalization of business has received a great deal of press in recent years. The pressure of global competition is frequently cited as primary drivers for greater customer demands for improved products and services. These increased demands have caused businesses to pursue improvement initiatives, such as implementation of Just-in-Time (JIT) and Quick Responses (QR) inventory management policies, business reengineering, and supply chain management as tools to enhance their competitiveness. At the same time, firms increasingly look to foreign markets for growth opportunities, or to foreign suppliers for improved sourcing opportunities. This increased interest in foreign business has been reflected in several trends.

As firms increase their participation in a global economy developing an understanding of supply chain management issues and opportunities in a global context becomes increasingly important.

Drivers for Economic Globalization

Over the past several decades, a number of factors have led to the increasing globalization of the world economy, and as a result, the competitive environment faced by firms has changed dramatically. These drivers for globalization are decreasing tariffs, improving transportation communications and information technology, globalization of products, services and markets, global competition, economic regionalism.

Supply chain management tools and techniques are seen as mechanisms that will allow a firm to respond to the environmental changes. By working more collaboratively with supply chain partners, a firm can better understand changes in customer requirements and respond more quickly to the changes. As firm have searched for ways to enhance their competitive position, supply chain management concepts have emerged as increasingly important. By sharing risks across supply chain partners, firm may be able to improve their own performance in increasingly volatile and competitive global markets.

Dynamic Role of Sales Function in SCM

The role of the contemporary sales person is changing dramatically, and in many situations, the old models of selling are simply outdated, ineffective and counter productive to SCM goals and objectives. Although most sales organizations focus on prepurchase activities, supply chain partners focus on managing relationships and conducting postpurchase activities to enhance supply chain performance. As companies adopt supply chain management, functional areas need to change their traditional ways of conducting business and better align their current management practices to support and enhance supply chain management.

Personal Selling In SCM

The sales function plays a critical role in implementing many supply chain management activities and behaviours. For the sales force to add value in the supply chain, the contemporary sales force must adopt a new orientation to personal selling, interface more effectively with logistics, and gain new supply chain management skills and expertise.

New Roles for Sales Management

To support the sales force in its new supply chain management roles, sales managers need to train, support and encourage supply chain activities and logistics expertise. To achieve this goal, sales managers must also adopt a new orientation and embrace new management technique to enhance supply chain performance. Specifically sales managers must become "Change Agents" in the sales organization and lead the sales force in a new direction. Training programs, performance objectives, and compensation package need to be adapted and better aligned with a supply chain management. The leading edge firms are redesigning the sales function to create value in a supply chain management environment. As more and more firms compete through supply chain management, the role of sales force will continue to evolve.

Role of Transportation In A Supply Chain

Transportation refers to the movement of product from one location to another as it makes it way form the beginning of a supply chain driver because products are rarely produced and consumed in the same location. Transportation is a significant component of the costs incurred by most supply chains. The role of transportation is even more significant in global supply chains.

International trade is becoming a bigger part of the world's economic activity. Any supply chains success is closely linked to the appropriate use of transportation. Supply chain also use responsive transportation to centralize inventories and operate with fewer facilities. To understand the transportation in a supply chain it is important to consider the perspective of all four parties. A carrier makes investment decisions regarding the transportation equipment (locomotives, trucks, airplanes, etc) and in some cases infrastructure (rail) and then makes operating decisions to try to maximize the return from these assets. A shipper, in contrast uses transportation to minimize the total cost (transportation, inventory, information, sourcing and facility) while providing an appropriate level of responsiveness to the customer.

Supply chain use a combination of various modes like air, package carriers, trucks, rails, water, pipelines and Intermodal for the transportation purpose.

Information Technology in Supply Chain Management

A key aspect of supply chain management is the ability to make strategic decisions quickly based on accurate data, and this requires an efficient and effective information system. Information is vital for a supply chain to function. Without information relayed at right time to the right place, there are no purchase orders, no shipment managers and no payments and the supply chain shuts down. Supply chain management is based on the exchange of substantial quantities of information among the buyer, supplier and carrier to increase the efficiency and effectiveness of supply chain.

The Business Environment

Information is at the center of virtually every aspect of business especially in today's dynamic, uncertain and highly cooperative environment. E-commerce applications and e-enabled capabilities that rely on efficient information transfer have the potential to completely revolutionize the existing business environment. Functional Integration, Time & Quality Based Competition and Increasing Computing Power are the major trends of business environment.

The first major trend is functional integration; it directly influenced the information systems that were developed to facilitate Supply Chain Management. Supply Chain activities sourcing, vendor selection and purchasing, as well as manufacturing related activities such as production planning, scheduling and packing must be part of the integration effort. Key enablers of the integration of functions in information technology. The major benefit of integrating functional activities through information technology is reducing the associated costs.

The second major trend in the business environment influencing the development of information system is emphasis on speed to market with high quality product. Time & Quality based competition can be defined as the elimination of waste in the form of time, effort, defective units, and inventory in manufacturing distribution systems. Two capabilities that are useful in a time and quality based competitive environment are agility and flexibility. With faster product innovations, decrease product life cycles, and rapid imitative competition, only firms that are agile and flexible will survive. Agility is the ability to respond quickly to changes in the marketing environment. Agile firms are able to successfully market low-cost, high-quality products with short lead times in varying volumes that provide enhance value to customers through customize. Flexibility is defined as the capability of changing from one task to another rapidly when changing conditions are defined ahead of time.

The third major trend in the business environment that has helped increase the growth of information systems in the tremendous increase in computing power at very low costs. The evolution of information technology and diminishing transaction costs will lead to fundamental restructuring of industry practices for distributing and supporting products. Advances in information system will likely to cause four changes: more transparent organizational structures, more strategic alliance, and increased emphasis on performance measurement and great reliance on time-based strategies.

Supply Chain Information Systems

Information systems are essential to managing a supply chain. The supply chain information systems rely on either EDI (Electronic Data Interchange) or the Internet to transmit information within the supply chain. A valuable initial element in managing a supply chain is developing supply chain information systems. The concept of supply chain management is built on functional integration, which is supported and often catalyzed by information technology.

One of the components of the implementation of supply chain management is information sharing through two-way communication between partners within a supply chain. The activities of information generation, storage, and utilization in individual firms in a supply chain are essential to implement supply chain management. Member of a supply chain need real-time visibility of performance data across the entire supply chain.

In Dell computer's direct relationship with its customer create valuable information that, in turn, allows the company to coordinate its entire supply chain back through manufacturing to product design with other firms.

Conclusion

World is shrinking day-by-day with advancement of technology. The expectations of customers are rising and the companies are prone to more and more uncertain environment. Under this uncertain & volatile environment, companies will found that their conventional supply chain integration will have to be expanded beyond the boundaries of their own organization. In the 21st century companies will have to start using IT for their strategy development in contrast to the earlier situation when IT was aligned with existing business strategies to gain competitive advantage. New developments such as the proliferation of Internet Technology, World Wide Web, Electronic Commerce, etc., will change the way a company is required to do business. The companies must also realize that they must harness the power of technology to collaborate with their business partners as never before. It can be concluded that a proper IT strategy integrated with a supply chain strategy can turn around a company's fortune.

0 Comments